Purging the Air from the IH Axial Piston Pump

The IH Axial Piston Pump that we sell includes a step-by-step installation procedure from the manufacturer, which you can view here. This is very good information, both about how to install the pump, and also how to start the engine for the first time. But I also recommend performing an extra step as part of the “First Start-Up Procedure.”

I recommend this extra procedure because I’ve found that premature starting of the engine may risk damaging your new pump, if the air in the pump is not fully purged. This extra step will guarantee that it is.

What follows is the same information as the manufacturer’s instructions, the only change I have made is to add the middle section about purging the pump of air.

❋ ❋ ❋ ❋ ❋

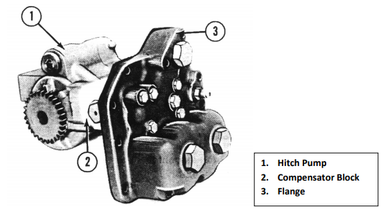

INSTALLATION OF PUMP ASSEMBLY:

1. Remove the filter cover, filter(s), by-pass valve, filter retaining plate, and jumper tube w/ seal

2. Install the pump assembly and a new gasket and o-ring

3. NOTE: Do not tighten capscrews at this time

4. Install the jumper tube with seal through the filter housing into the pump to insure proper alignment

5. Torque the pump flange mounting bolts to 18 to 21 lbs. per ft

6. NOTE: After torquing the pump mounting bolts check to be certain the jumper tube with seal is properly seated

7. Install the filter retaining plate, filter(s), by-pass valve, and filter cover being careful not to damage o-rings

8. Fill the rear housing with the required amount of hy-tran fluid

FIRST START-UP PROCEDURE FOLLOWING THE INSTALLATION:

1. Before starting the engine, place the hydraulic motor control valve lever in the “motor run” position and lock it in that position using the lock-out tab in the quadrant

2. Make sure that no implements or devices are connected to any of the remove outlets or hitch

3. PURGING AIR FROM THE PUMP: Before starting the engine, place the throttle lever in the fuel shut off position (so the engine will not start) and crank the engine over with the starter for a total of 2 minutes. (Stop every 10-15 second and let the starter cool). After you have rotated the engine for a TOTAL of 2 minutes (not counting the time you spent letting the starter cool), continue cranking the engine, but now, while it is cranking, ease the throttle up until the engine starts, and let it run at the lowest possible RPM's for a minute or two. You should hear the pump burp.

4. Shut off the engine and return the hydraulic motor control valve lever to neutral

5. The above procedures assures that all cavities in the pump will be filled prior to when high pressure demands can be placed on the hydraulic system

❋ ❋ ❋ ❋ ❋

Also, just a reminder that your old pump has a core value of $150, even if the pump shaft is broken. You are responsible for the shipping, and we will refund $150 when we receive your old pump.

If you have any questions, call or email.

(715) 495-4932

Joe